Scroll through the slides below to find out how the TV ERF will process rubbish from the North-East once it becomes operational

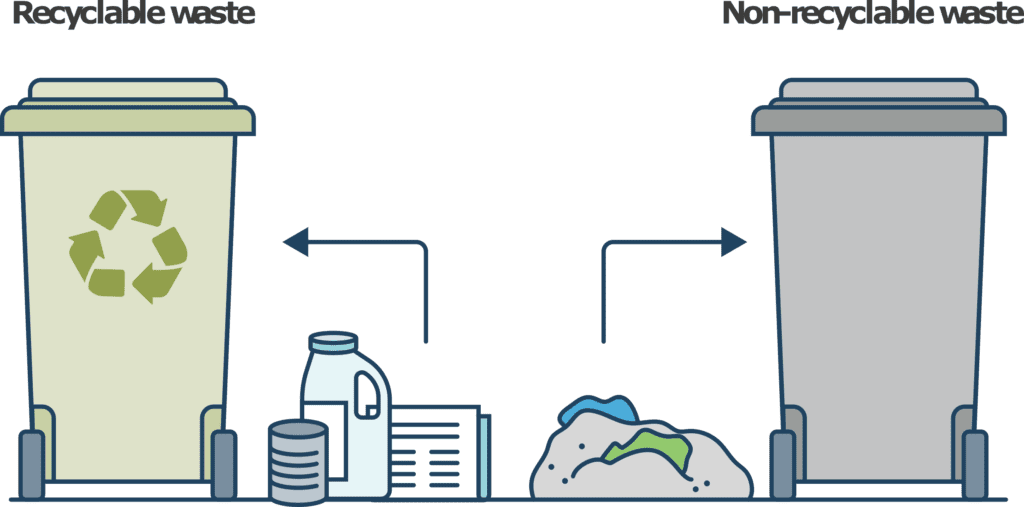

Using kerbside and other recycling services, local householders and businesses are encouraged to recycle as much of their waste material as they can by ensuring that aluminium cans, glass, tins, paper, cardboard and plastics are kept separate from the general waste that cannot be recycled.

However, whatever cannot be recycled, composted or re-used is placed in a general rubbish bin and put out for collection.

Recycling containers and general rubbish bins are collected separately and the recycling typically goes to sorting and reprocessing plants to be made into new things.

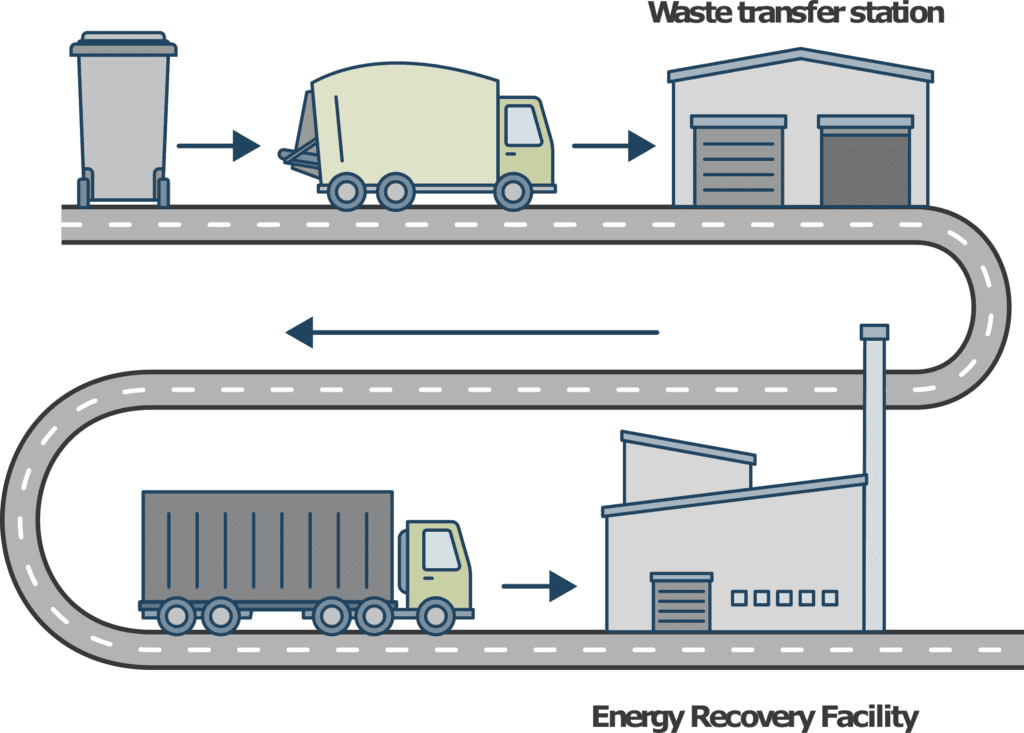

The contents of general rubbish bins are collected and will be transported either to the TV ERF directly or via a local transfer station first. Once the waste arrives at the TV ERF it will be tipped into a large bunker capable of holding several thousand tonnes of waste at a time.

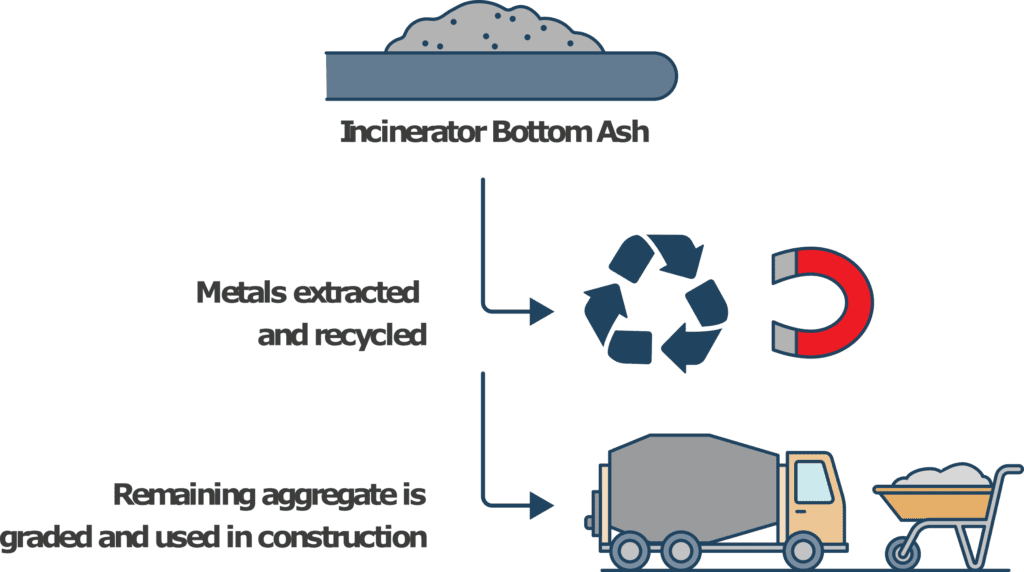

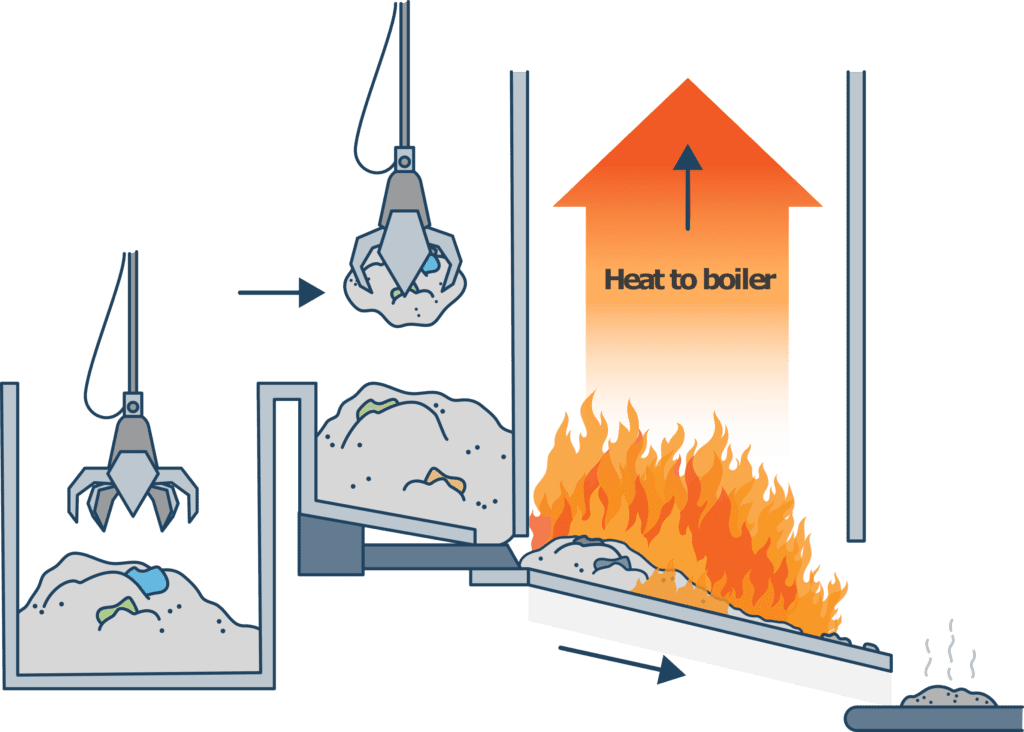

Grab claws suspended from cranes will mix the waste and then load it into a furnace, where it is burned to generate lots of heat. A moving grate transports burning waste material through the furnace until only ash remains – ensuring that the waste material is fully combusted.

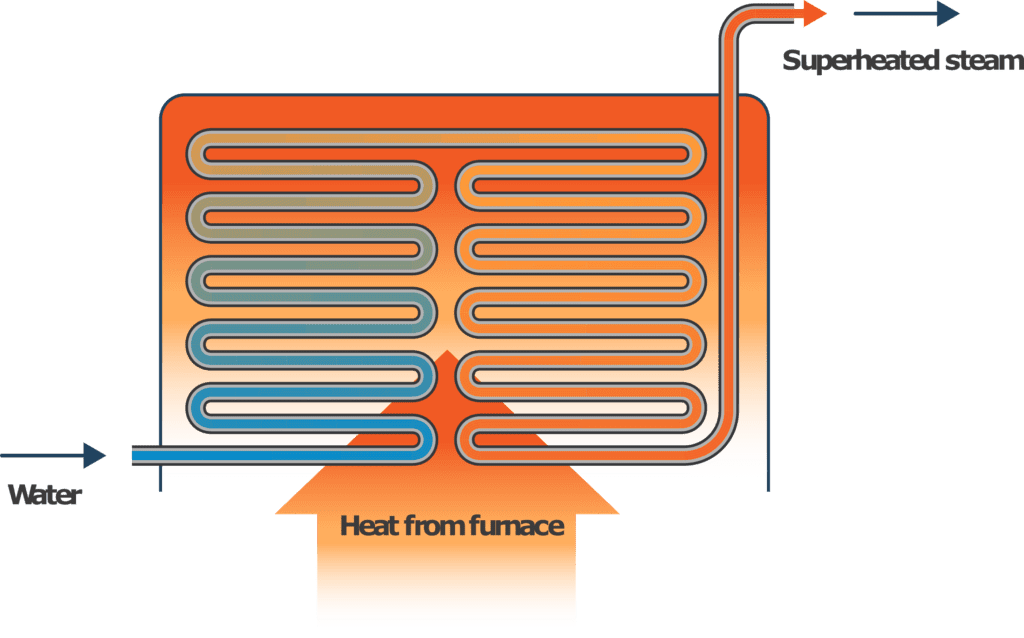

The heat produced by the waste in the furnace heats water in a boiler to produce steam, which then passes through a superheater to heat it even further and remove moisture.

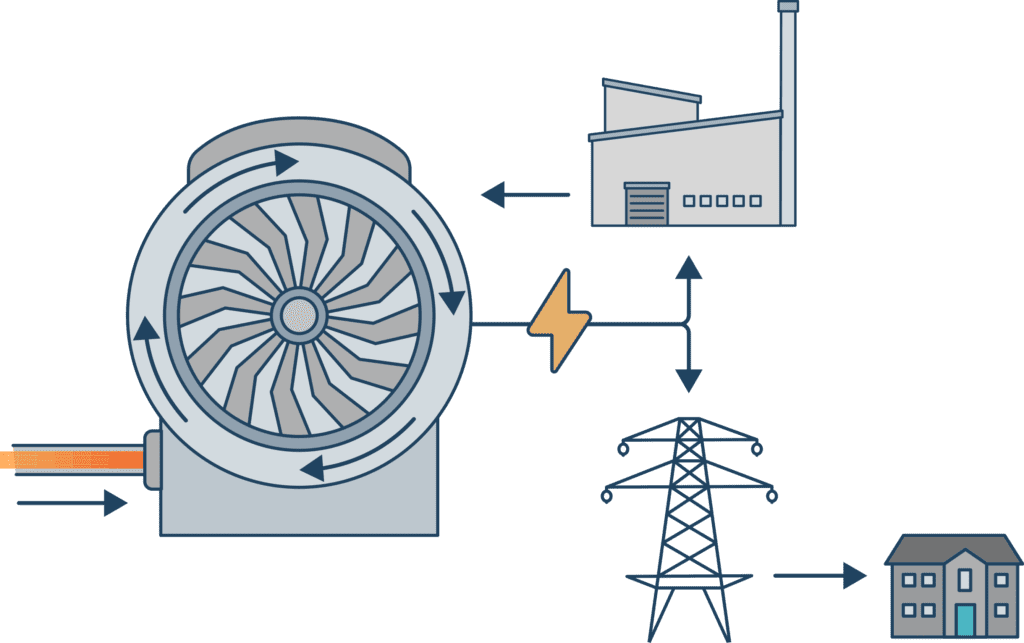

The dry superheated steam is then used to drive a turbine, much like most other conventional power stations. The turbine produces electrical power which is used to power the electrical processes in the plant itself while the remaining balance is exported off-site to electricity networks – powering other homes and businesses.

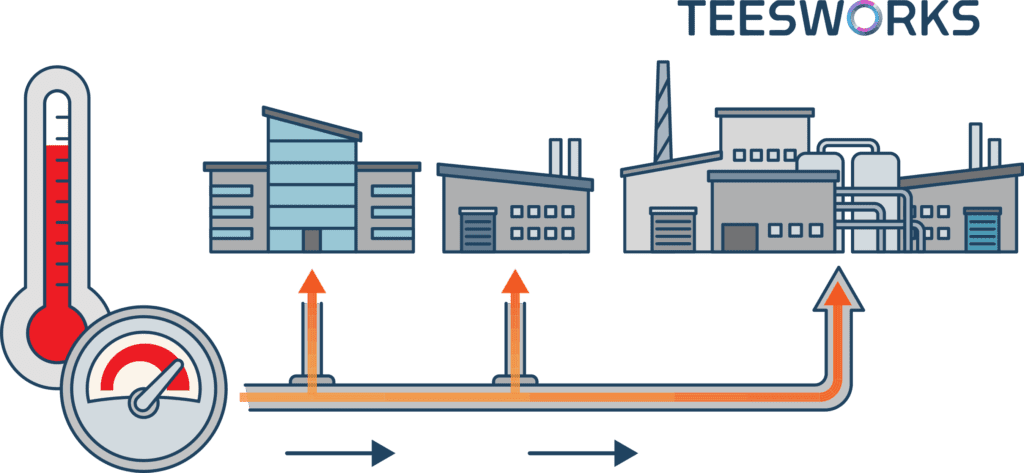

This process generates lots of heat and excess heat can be used for district heating networks – similar to the boiler heating your home. The heat can be transferred through pipe networks to heat neighbouring businesses and the project partners hope that new businesses at the Teesworks site will be able to make use of this heat in future.

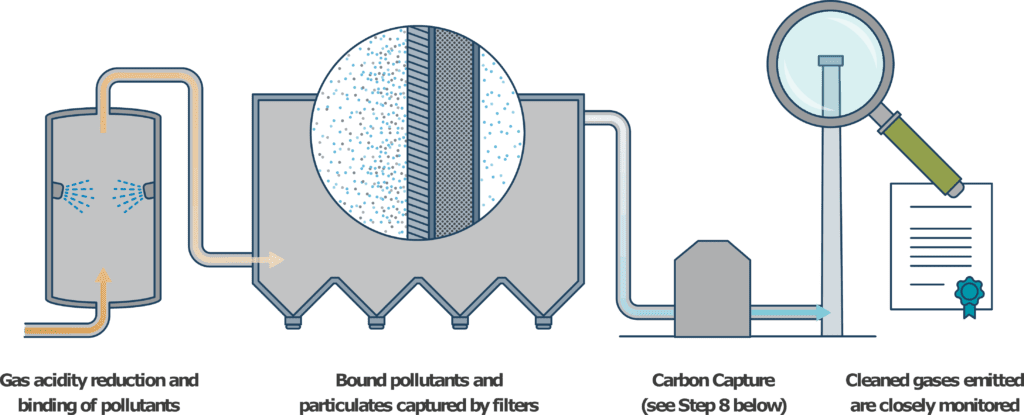

Much like your gas boiler at home, when fuel is burned to generate energy, it creates exhaust gases. At the TV ERF, like all energy recovery plants, the gases from the combustion process will be cleaned and filtered to remove particulates and potentially hazardous elements before being released to the atmosphere via the chimney stack.

To do this, the TV ERF will employ a range of proven, industry-standard, technologies that reduce the acidity of the gas and bind potential pollutants and particulate matter. The gases then pass through very fine filters which capture the bound pollutants. The filters are regularly cleaned and replaced, and the material captured in them, known as Air Pollution Control Residue (APCR) is collected for treatment or secure storage. Emissions from the plant are constantly monitored and are subject to strict regulation.

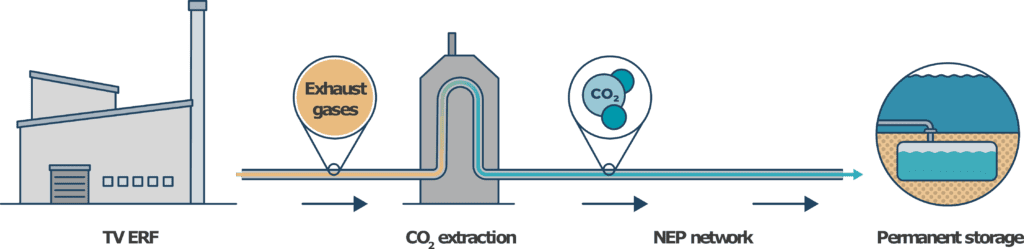

Situated within the East Coast Cluster, the TV ERF could make use of Carbon Capture and Storage (CCS) technology in future.

This technology would capture carbon emissions before they are released from the stack and condense them into a liquid so that they can be transported in pipes to the new Northern Endurance Partnership (NEP) underground storage facility in the North Sea.